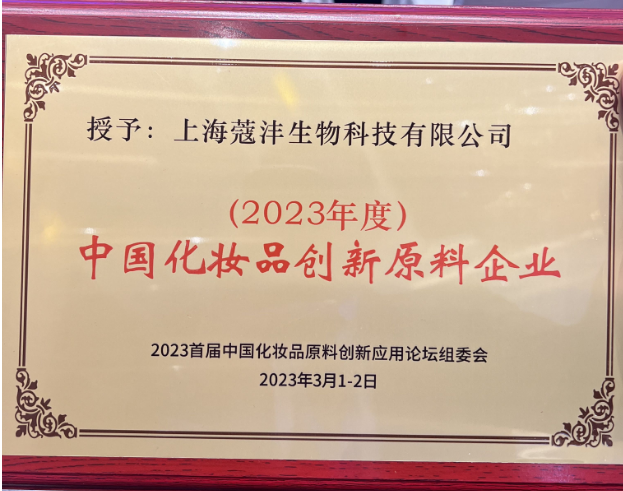

On March 1-2, the "2023 First China Cosmetics Raw Material Innovation and Application Forum" jointly organized by Beauty Headlines and Shandong Cosmetics Industry Association, jointly named Micropowder General, and co organized by the Key Laboratory of Cosmetics Raw Material Quality Control of the State Food and Drug Administration and Shandong Food and Drug Inspection and Research Institute was successfully held at Shunhe International Hotel in Jinan, Shandong.

As a supplier specializing in the research and development and production of high-quality cosmetic powder raw materials, Lianhe Micropowder is committed to the research and development of cosmetic powder, breaking the monopoly of international high-end powder raw materials, successfully creating several explosive products with multiple cutting-edge beauty brands, and also providing professional products and services to multiple globally renowned beauty enterprises.

Founded 13 years ago and dedicated to the research and development of cosmetics powder, what is its uniqueness? At this forum, Mr. Puke, the co-founder of Micropowder, provided the answer when sharing "Exploration of the R&D and Application of Natural Green Powder".

Good powder, creating high-quality makeup

With the rise of cosmetics in the Chinese market and the upgrading of cosmetics consumption, the cosmetics market is growing rapidly, and it is expected that the overall market will reach 609.2 billion yuan by 2025. Faced with this huge market, new and old brands are accelerating their layout, and the fierce competition in the makeup industry is increasing unabated. How to use cutting-edge development concepts and high-quality products to successfully capture the minds of consumers and break through from a group of makeup brands has become a key point.

As is well known, the first keyword for consumers to choose cosmetics is "quality". To have excellent cosmetic "quality", high-quality raw materials are essential. Puke stated that the quality of powder materials directly determines the quality of a makeup product. A good powder material needs to have the following four characteristics:

Safe and stable

Firstly, cosmetics are intended for the human body and must have sufficient safety assessments; Next is stability, including stable quality and stable supply. In terms of stable quality, the product performance of powders needs to be maintained in a stable state in different batches, seasons, and application scenarios. In terms of stable supply, powder materials, as the core component of makeup, need to have a stable supply chain for supply.

Product integrity

Complete product information (basic product data description, quality and safety documents, testing standards and methods, etc.), complete internal control standards (validation of production equipment, validation of process flow, establishment of internal testing indicators and methods, etc.), complete evaluation and testing (applicable scenarios, application of formula system, cosmetic effects, etc.). These three integrity requirements constitute a qualified and complete commodity that meets the basic conditions for circulation in the market.

Accurate positioning, innovative and practical

The birth/design of powder materials should have an accurate positioning, whether it can improve/solve current pain points, technical difficulties, or endow products with new value. In addition, in terms of practicality, industrialization is also needed.

In line with the development trend of the entire market

The green and sustainable development process of cosmetics is a global market trend, and suppliers' continuous research and development of natural green powder materials is in line with market trends and trends. It is worth mentioning that in the exploration of the research and application of natural green powders, the United Micropowder has deeply explored four innovative directions in research and development.

1. Deep processing of natural powders through reconstruction, peeling, and purification.

2. In terms of technological innovation of powder materials, greener processes are adopted, more physical processes are introduced, more rigorous waste treatment and more recycling are adopted.

3. In the surface treatment of powder raw materials, use greener ingredients, more rigorous waste treatment, and greener processes to create.

4. The application of innovative materials, selecting natural sources of cellulose, starch, silica, and some plant powders.

R&D is the king, making good powder and makeup

There is a popular saying in the business world, "When the tide recedes, you know who is swimming naked.

——At present, China's cosmetics supply chain is in a stage of breakthrough and transformation, and more advanced productivity is bound to emerge. China's cosmetics supply chain enterprises will have world-class innovative research and development, production and manufacturing capabilities in cosmetics.

As one of the industry representatives of "roll research and development", since its establishment in 2010, United Micro Powder has always attached great importance to powder research and development. Its founder, Puke, has 21 years of experience in raw material research and development, and regards research and development capabilities as an important driving force for enterprise development. This attitude is implemented throughout the entire production and operation process, cultivating and establishing its own research and development system and talent team, Its core management team mostly comes from technical authorities or experts from leading enterprises in the industry.

With thirteen years of accumulation in raw materials, Lianhe Micropowder has mastered over 300 customized and standard powder products, over 600 highly stable makeup formula systems, and possesses precision color difference control technology, UNI-Speejet ™ Multiple domestic and foreign invention patents, including supersonic cyclone airflow crushing technology.

Source empowerment, driving innovation.

With strong innovation capabilities in powder material research and development, the innovation of cosmetic products will also be greatly enhanced. At present, United Micro Powder not only breaks the international monopoly of high-end powder raw materials, but also maintains a leading market share in the industry for high-performance powder. Its high-performance powder raw materials continue to appear in many well-known international brand products, accompanying numerous brands to incubate cosmetics "explosive products" and win the market!

High end powder "escort"

In the future, we hope to bring more innovative products with core technology and competitiveness through our investment in research and development innovation, empowering our downstream brands and customers, and making their products more competitive!

Thank you for your continuous support for the United Micropowder.

Post time: Sep-11-2023